Major panel types

common characteristics: easy to operate, light weight, water proof, fire proof, green build materials,

cost and time saving process

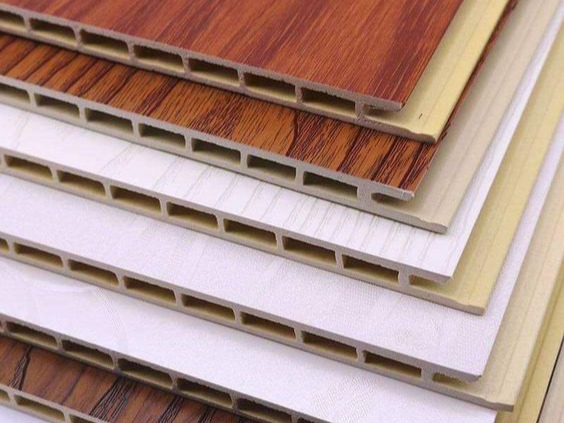

Bamboo-wood fiber panel

The base material is made of bamboo-wood fiber mixed resin extruded at high temperature. It is waterproof/fireproof/environmentally friendly and durable. The thickness is only 9mm. It can be directly laid on raw concrete wall. If the wall is not straight, you can fill it with foam glue or level the keel. It is quick to install and greatly reduces 80% operation time when comparing to painting or wall papering.

Carbon crystal panel

The new high-grade decorative building material can be understood as an upgraded version of bamboo-wood fiberboard. The material is hard, durable and light. The thickness is only 8mm. It has strong processability and greatly improves engineering efficiency! Waterproof, fireproof, environmentally friendly, and zero formaldehyde, it can be used on kitchen and bathroom walls to replace tiles.

There are a variety of series including solid color, fabric, embossed, wood grain, brushed metal, mirror (can replace glass mirror), hundreds of finishing options. Widely used in various commercial and home interior design projects.

Aluminum fluted panel

The aluminum profile is extruded and has a variety of wave shapes that can diffuse and absorb indoor noise. The 2mm extra-thick material is hard and durable.

Fast assembly with snap-cuff joints improves engineering efficiency, and the materials are fireproof, waterproof and durable, especially suitable for various commercial places.

Lightweight aluminum panels are also suitable for ceiling projects, including plastic aluminum panels, punched aluminum panels, and metal flat mesh panels, all of which are customized according to the project.

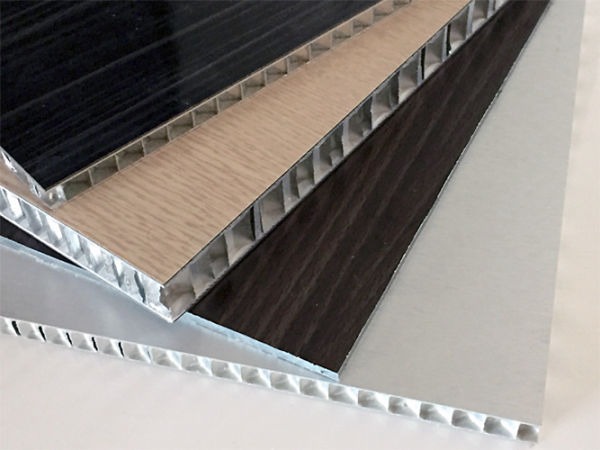

Aluminum honeycomb panel

Aluminum honeycomb sandwich structure, which is a composite panel made of high-strength alloy aluminum plate coated with a decorative coating with excellent weather resistance as the surface, bottom plate and aluminum honeycomb core such as a sandwich through high temperature and high pressure.

Features: Lightweight and high rigidity, excellent waterproof/fireproof/cut-resistant durability.

Specifications: 7~40mm thickness, multi-color/wood grain and embossed grain.

Application: Decorative wall panels and ceilings of commercial buildings/public facilities.

Sintered stone panel

Sintered Stone is a popular new material in recent years. It is harder than granite and other igneous rocks, and its Mohs hardness exceeds 6 degrees, which can resist scratches. Rock slab is made of natural raw materials such as natural stone powder and felsic, and is fired by high pressure and high temperature above 1200 ℃ through special technology.

Advantages: strong fire resistance, corrosion resistance: resistant to various chemical substances, including solutions, disinfectants, etc. Combined with the honeycomb aluminum base material, it is light and convenient for engineering operations, including wall and floor laying, which greatly improves engineering efficiency and has a great advantage in cost compared with traditional stone materials.